COMBI® PCS® AUTOMATED DRY ICE BLASTING SOLUTION

Greater control.

Greater versatility.

Greater automation.

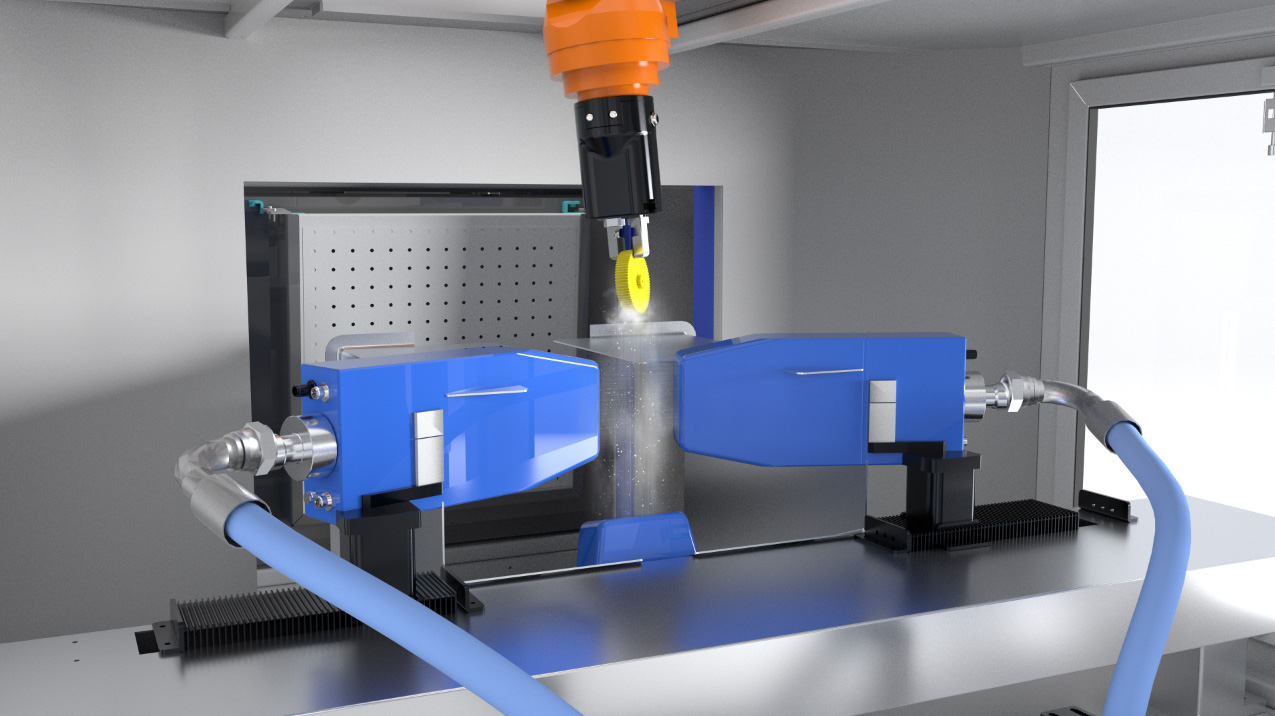

AUTOMATED ALL-IN-ONE

DRY ICE BLASTING SOLUTION

The COMBI PCS Series of machines combine our industry leading dry ice pelletizers with our advanced dry ice blasters for an autonomous and environmentally sustainable cleaning, surface preparation, and parts finishing system. Our dry ice pelletizers offer the best conversion ratio of liquid CO2 on the market while producing the highest quality dry ice.

Our most technologically advanced dry ice blaster incorporates our Particle Control™ system, offering greater control for any application. The COMBI PCS Series of machines will take any cleaning, surface preparation, and parts finishing processes to the next level.

Greater control.

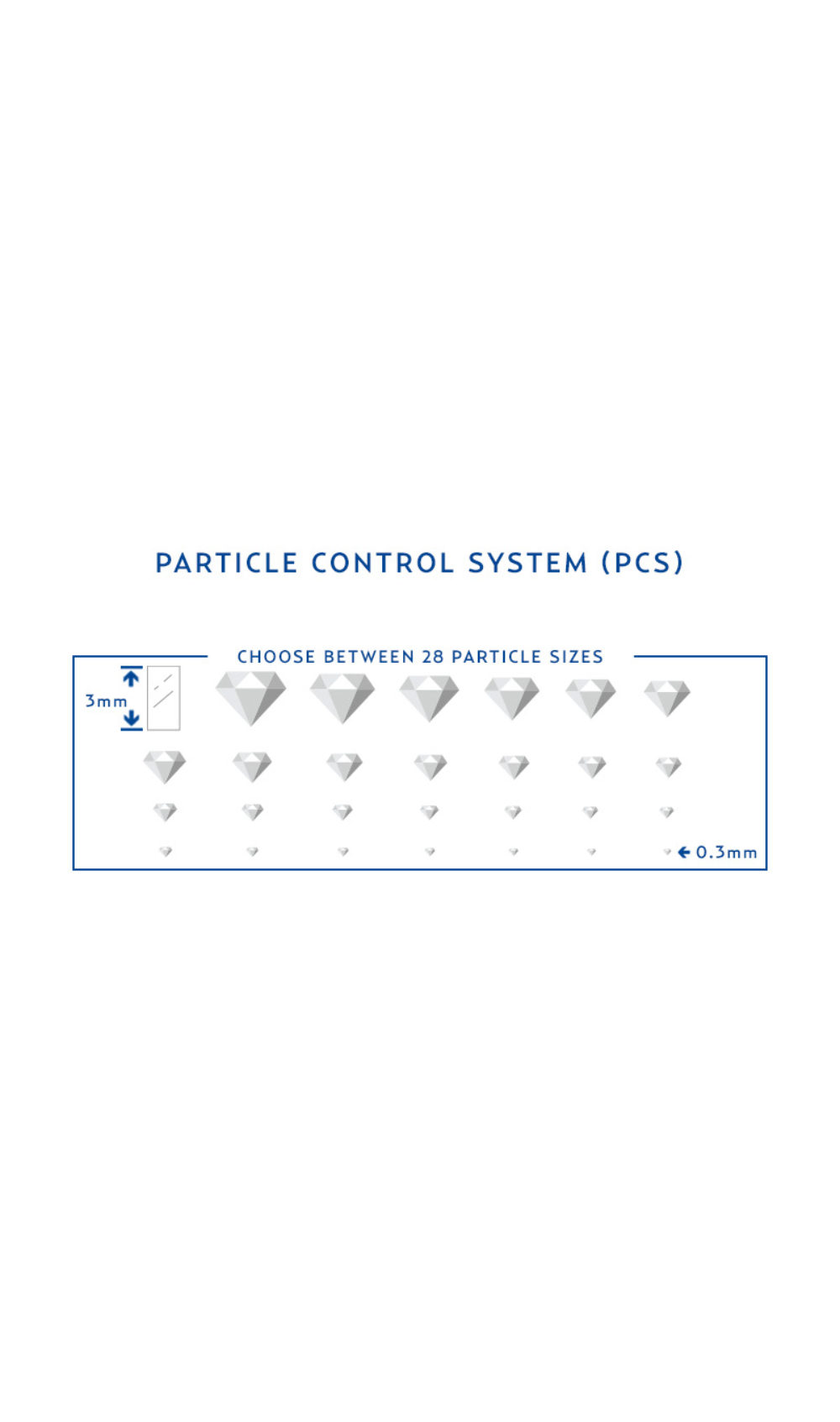

Three words: Particle. Control. System.

Take control of your processes with the COMBI PCS system. Our patented Particle Control system offers greater control for automated environmentally sustainable cleaning, surface preparation, and parts finishing processes.

Depending on the contaminant and substrate to be cleaned, programmers can precisely cut dry ice particles from 3.0mm to 0.3mm and every size in between with our PCS system.

Control your production. Control your blasting. Control your efficiencies.

Greater versatility.

Three machines. Countless applications.

The COMBI PCS series provides three system configurations for countless applications. From two simultaneous blasting operations with the COMBI PCS 110 to four simultaneous blasting operations with the COMBI PCS 320 DUAL.

Control your production. Control your blasting. Control your efficiencies.

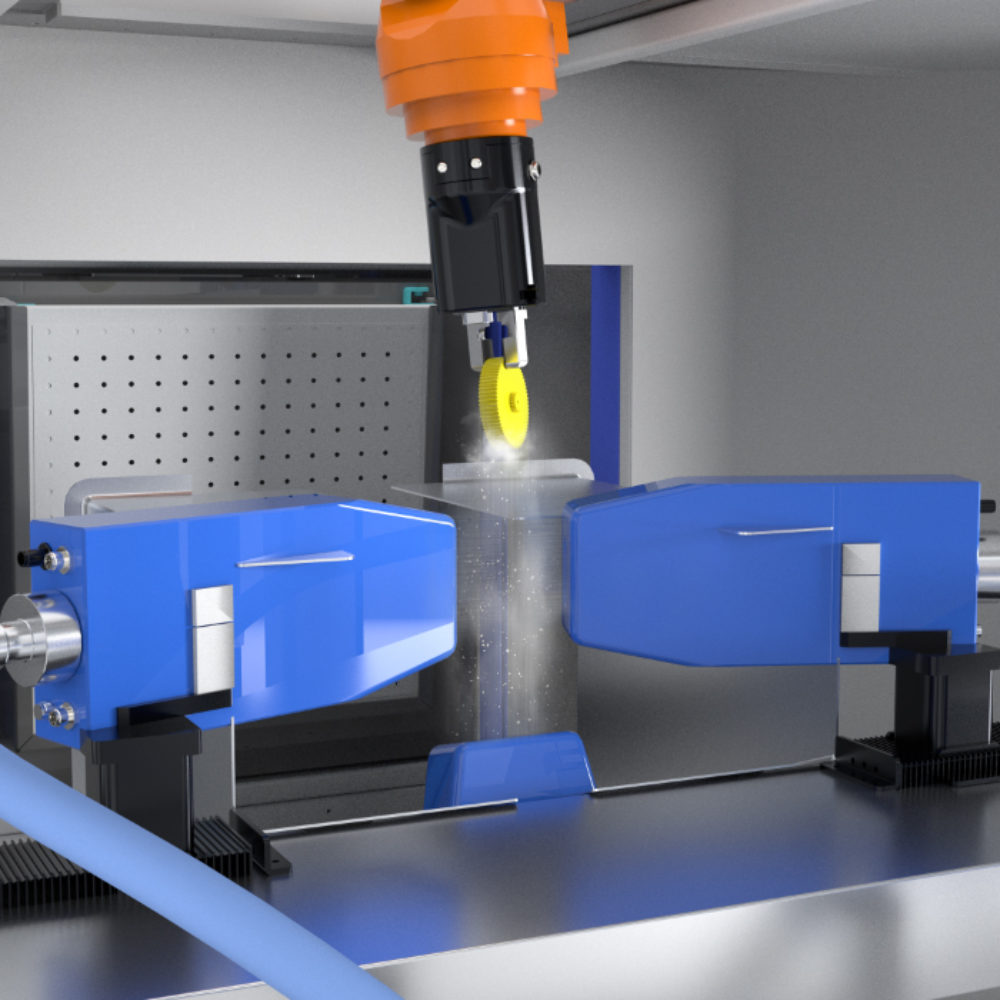

Greater automation.

Integration for the future.

The COMBI PCS systems are built for integration. Easily adapt this system with a robotic arm for continuous operation in blast cabinets or automated conveyor cleaning lines. Reduce manual labor hours and bottlenecks while improving part quality and minimizing scrap.

Control your production. Control your blasting. Control your efficiencies.

Which COMBI PCS system is right for you?

COMBI PCS 110

Run up to 2 automated blasting operations simultaneously

Dry Ice Output

Produce up to 110 kg/hr (242.5 lb/hr)

Blasting Output

Blast up to 110 kg/hr (242.5 lb/hr)

(dependent on particle size)

Dry Ice Particle Size

0.3 mm – 3.0 mm

Simultaneous Blasting Operation

Up to 2 with splitter

HMI Display

16″ Multi-touch Beckhoff Industrial PC

Noise Level

Below 75 dB(A) (without nozzle)

Inlet Liquid CO2 Pressure

13 – 18 bar (189 – 261 psi)

-33 / -22 C (-27 / -9 F)

Optimal Performance Range

15 – 16 bar (218 – 232 psi)

-29 / -27 C (-20 / -17 F)

Compressed Air Supply

5 – 10 bar (72.5 – 145 psi)

Air Quality

ISO 8573-1, Minimum class 2

Nozzle Air Consumption

3 – 11 m3/min (106 – 388 CFM)

Compressed Air Connection

1.5″ BSP Thread

Machine Dimensions (L x W x H)

1800 x 1200 x 2200 mm

70.9 x 47.3 x 86.6 in

Power Supply

3 x 380 – 480 V AC + PE, 50 – 60 Hz

Rated Power

10 kW / 13 HP

COMBI PCS 110 DUAL

Run up to 4 automated blasting operations simultaneously

Dry Ice Output

Produce up to 110 kg/hr (242.5 lb/hr)

Blasting Output

Blast up to 110 kg/hr (242.5 lb/hr)

(dependent on particle size)

Dry Ice Particle Size

0.3 mm – 3.0 mm

Simultaneous Blasting Operation

Up to 4 with splitters

HMI Display

16″ Multi-touch Beckhoff Industrial PC

Noise Level

Below 75 dB(A) (without nozzle)

Inlet Liquid CO2 Pressure

13 – 18 bar (189 – 261 psi)

-33 / -22 C (-27 / -9 F)

Optimal Performance Range

15 – 16 bar (218 – 232 psi)

-29 / -27 C (-20 / -17 F)

Compressed Air Supply

5 – 10 bar (72.5 – 145 psi)

Air Quality

ISO 8573-1, Minimum class 2

Nozzle Air Consumption

3 – 11 m3/min (106 – 388 CFM)

Compressed Air Connection

1.5″ BSP Thread

Machine Dimensions (L x W x H)

1800 x 1200 x 2200 mm

70.9 x 47.3 x 86.6 in

Power Supply

3 x 380 – 480 V AC + PE, 50 – 60 Hz

Rated Power

10 kW / 13 HP

Automation at work.

-

![]() Generación de energía eléctrica

Generación de energía eléctrica -

![]()

-

![]()

-

![]()

-

![]()

Limpia Harina, Azúcares y Aceites de Equipos de Procesamiento de Alimentos

Más información -

![]()

Limpieza de Moldes de Asientos de Coche con Chorro de Hielo Seco

Más información -

-

![]()

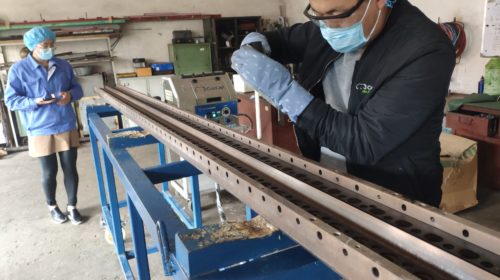

Remoción de Flashes del Proceso de Moldeo con Hielo Seco

Más información -

![]()

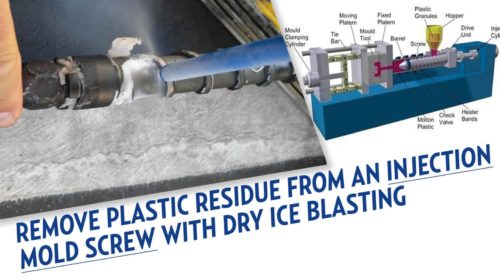

Limpieza del Tornillo de Inyección con Hielo Seco

Más información -

![]() Dispositivos médicos

Dispositivos médicosUn fabricante de fibras no tejidas de polímeros aumentó su capacidad de producción

Más información

ESTAMOS AQUÍ PARA AYUDAR.

¿Está interesado, pero no sabe por dónde empezar?

Póngase en contacto con nosotros hoy mismo para obtener más información sobre cómo la limpieza criogénica puede mejorar su proceso de limpieza de moldes.