Using dry ice blasting brought 300% gains in productivity and a 65% cost reduction compared with our previous method.

Dry Ice Blasters for the Oil and Gas Industry

Extend Asset Life and Clean Without Downtime Using Moisture-Free Dry Ice Blasting for Oil & Gas

Dry ice cleaning is non-abrasive, non-conductive, chemical-free, moisture-free, and does not produce secondary waste streams.

Dirty oil field and refinery equipment creates multiple challenges in the Oil and Gas industry. Contaminants such as heavy oils, bitumen, paraffin, acids, and chemicals can cause corrosive damage to pipelines and other operational assets. If operational equipment is not regularly cleaned and maintained, it can degrade performance efficiency, lead to equipment failure, and create unsafe working conditions that endanger the health and safety of your workforce.

Dry ice blasting is an environmentally friendly cleaning and maintenance solution that delivers a high quality clean, results in zero moisture or humidity, and meets the highest environmental, health, and safety standards.

Industrial dry ice blasting machines are a durable and portable cleaning solution for a wide range of applications in Petrochemical, Oil and Gas, and Refineries, including removing heavy buildup from processing equipment to surface preparation for non-destructive testing in upstream, midstream, and downstream environments.

Cold Jet’s dry ice blasting equipment for Oil and Gas companies helps your operation run at peak performance and safety.

What are the Benefits of Dry Ice Blasting for Oil and Gas Companies?

Dry ice blasting revolutionizes cleaning and maintenance in Oil and Gas operations by reducing downtime and enhancing operational performance.

Oil and Gas companies face unique cleaning challenges that traditional methods struggle to address effectively.

The unique characteristics of dry ice make it an ideal industrial cleaning solution in Oil and Gas, Petrochemical, and Refinery operations. The non-abrasive nature of dry ice protects valuable assets from corrosion and damage that would otherwise occur with abrasive or water-based cleaning methods, extending equipment life and reducing maintenance costs.

Dry ice sublimates upon impact, or disappears into the atmosphere. This eliminates hazardous waste streams, moisture, media entrapment, and extensive pre-job preparation.

-

Non-Abrasive and Safe for Equipment

Dry ice cleaning is non-abrasive. It extends substrate life and prolongs asset longevity in Refinery, Oilfield, and Midstream environments. Unlike traditional cleaning and maintenance methods, it causes no caustic etching, acidic damage to surfaces, or abrasion. The industrial cleaning process is safe for even the most delicate components, such as heat exchanger fins, electrical motors, generator windings, transformers, switch gears, circuitry, and wiring.

-

Zero Moisture and No Secondary Waste

Dry ice blasters add zero moisture or secondary waste. The dry cleaning process does not use water, solvents, or harmful media like silica and because dry ice sublimates, there is no left over media that must be contained, collected, and disposed of. Dry ice sublimates upon contact with the substrate, so there is no risk of media entrapment or water damage to sensitive parts and equipment. This results in a safer environment for workers and surrounding ecosystems, reduced disposal costs, and minimal pre-job preparation.

-

Clean Online and In-Place

Dry ice blasting can clean operational equipment while it remains operational, eliminating or drastically reducing disassembly requirements, production downtime, and the risk of equipment failure. The in-situ cleaning method enables Upstream, Midstream, and Downstream operators to clean and maintain equipment year-round, not just during shutdown or turnaround periods.

-

Improve Efficiency of Operating Equipment

By maintaining Oil and Gas operating equipment at peak efficiency through more frequent and effective cleaning, companies can significantly reduce the risk of unplanned production stoppages and costly emergency repairs. This translates to increased operational uptime, improved productivity, and enhanced safety standards across Oil and Gas extraction, transportation, and refining operations—ultimately delivering substantial cost savings and operational benefits throughout the production lifecycle.

-

Employee and Environmentally Safe

Dry ice blast cleaning delivers superior safety benefits for both workers and the environment. The industrial maintenance and cleaning process does not use chemicals, solvents, or harmful cleaning media. By eliminating water, it reduces the risk of slippery or muddy work environments and because dry ice is non-conductive, it prevents damage, electrical shorts, and potential fires when cleaning sensitive equipment. Additionally, dry ice does not produce dust clouds, which can be inhaled by employees. Dry ice cleaning creates a safer workspace while maintaining environmental compliance in all Oil and Gas environments.

-

More Effective Cleaning

Dry ice blasting equipment delivers superior cleaning results compared to traditional methods. The process requires less labor while achieving faster and more thorough cleaning outcomes. Unlike conventional techniques, dry ice cleaning will not lead to embedded fouling and leaves no chemical residue or moisture behind, which reduces the risk of corrosion and abrasion. The cleaning process also eliminates micro-organisms, which can lead to coating and paint failure on vital piping and pipelines.

What Can Dry Ice Blasting Clean in Oil and Gas?

Dry Ice Cleaning consistently outperforms traditional methods, such as sand blasting and pressure washing. The industrial cleaning process delivers superior results across the entire Oil and Gas value chain.

-

Upstream Oil & Gas

-

Midstream Oil & Gas

-

Downstream Oil & Gas

Remove heavy oil, carbon, bitumen and paraffin buildup with Dry Ice Blasting

Dry ice cleaning provides an efficient solution for removing heavy oils, bitumen, carbon, and corroding agents from Oil and Gas operational assets.

Clean unwanted deposits from all types of equipment, including heat exchangers, pumps, vessels, motors, and piping, while preserving the structural integrity of the equipment being cleaned.

The versatility of dry ice blasters extends to numerous Oil and Gas applications including removing soluble salts and chloride buildup, product spill cleanup, failed coating and paint removal, light corrosion removal, and preparation for non-destructive testing.

-

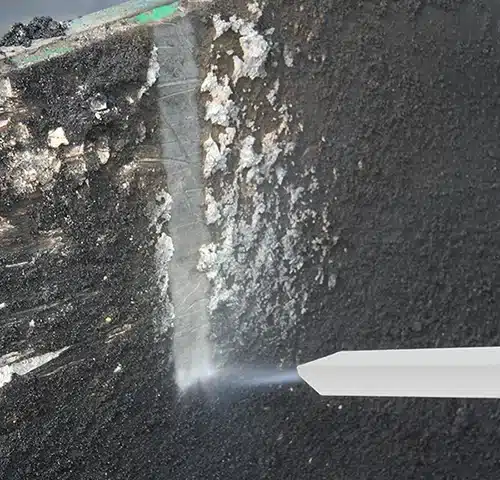

Removing heavy carbon buildup and bitumen from transportation equipment with dry ice cleaning

-

Dry ice blasting cleaning storage tank at refinery

-

Dry ice blasting removing corrosive material from oil field equipment

Clean and prepare surfaces for maintenance, repair, and repainting with Dry Ice Cleaning

Surface preparation is a critical process for a fabric maintenance team in maintaining Oil and Gas assets, particularly in non-destructive testing, pre-inspection cleaning, and cleaning before re-coating on pipelines, tanks, and vessels.

Dry ice blasting is an ideal solution for surface preparation in upstream, midstream, downstream, and offshore environments. Dry ice penetrates pores and crevices on steel surfaces, removing all potential contaminants including micro-organisms, oils, failed coatings, corrosion, soluble salts, and chlorides. Dry ice blast cleaning is a dry process and does not leave moisture, chemicals, or embedded fouling on the substrate, allowing for immediate repainting or recoating after cleaning and creating a foundation for a superior bond for coating and paint. Unlike sandblasting and water blasting, which can embed micro-organisms and debris into the substrate.

Dry ice cleaning allows fabric maintenance work to proceed without equipment or line shutdown, which enables more frequent cleaning and inspection. This is crucial since uncontrolled corrosion can lead to leaks, service interruptions, and costly environmental disasters.

-

Dry ice blast cleaning removing light corrosion from pipes at refinery

-

Removing surface corrosion and tar from iron pipe with dry ice cleaning

-

Dry ice blasting removing sulfur deposits prior to welding

Safely clean heat transfer, heat exchanger, and power generation equipment with dry ice blasting

Dry ice blasting equipment is a proven method of cleaning heat exchangers, boiler tubes, radiator fins, generators, motors, pumps, and heat transfer equipment.

-

Dry Ice Blasting for Frac Pump Radiators

Dry ice cleaning is effective at cleaning radiator fins on frac pump trucks. The industrial cleaning process requires little to no disassembly compared to alternative methods, does not utilize water or produce secondary waste, and it will not damage the delicate radiator fins.

-

HRSG Cleaning with Dry Ice Blasting

Dry ice cleaning provides superior cleaning and maintenance for Heat Recovery Steam Generators (HRSGs) by thoroughly cleaning finned tubes to restore optimal efficiency. The process enables quicker cleaning operations without costly disassembly or risk to tube bundle welds or pressure parts, making dry ice blasters a safe, effective alternative for HRSG cleaning. Dry ice cleaning does not produce secondary waste or use water, which maintains a dry state and easy cleanup.

-

Dry Ice Blasting for Fin Fan Cleaning

Dry ice blasting machines offer significant advantages for fin fan heat exchanger cleaning in energy value chain. The non-abrasive cleaning method can improve fin fan efficiency by removing years of accumulated dust and debris, allowing air to flow freely through the fins. The gentle cleaning method prevents damage to critical components such as motors, bearings, and instrumentation and can be performed while systems remain online, eliminating costly downtime.

-

Cleaning radiators on frac pump trucks with dry ice blasting

-

Dry ice blasting cleaning turbine at refinery

-

Removing atmospheric contamination from fin fans with dry ice cleaning

-

Aerial Coolers & Fin Fans

-

Boilers

-

Catalytic Crackers, Reformers, & CCR Platformers

-

Compressors (Casings, Stands, & Structure)

-

Convection Section of Re-Boilers

-

Drilling Equipment

-

Electric Control Cabinets

-

Ethanol Refining Equipment

-

Evaporators & Condensers

-

Exterior Tube Shells

-

Furnace & Economizer Tube Bundles

-

Generators

-

Heat Exchangers

-

Coker Units, Hydrocrackers, & Separators

-

HRSG Tube Cleaning

-

Pipelines

-

Pipes

-

Tanks & Vessels – Pressure, Production & Storage

-

Radiators (Frac Pump Trucks)

-

Rotating Equipment – Turbines & Motors

-

Thermal Oxidizers

-

Transport Vehicles

-

Valves & Gauges

-

Wellhead Equipment

What Do Oil and Gas Companies Need for Dry Ice Cleaning?

When implementing dry ice blasting for cleaning and maintenance in oil field, offshore oil, transportation, or refinery operations, you will need equipment beyond just the dry ice blast cleaning machine. The following components are essential for a safe and efficient dry ice cleaning program in Oil and Gas:

-

Portable and Durable Dry Ice Blaster

The foundation of your industrial cleaning and maintenance program starts with a reliable and easy to use dry ice blasting system. Cold Jet offers a variety of dry ice blasting cleaning machine models to choose from, including models with feature adjustable blasting pressures, stainless steel components, and rugged and durable frames. The systems will come complete with an applicator, a blast and air hose, and a nozzle that is best suited for your Oil and Gas application.

-

Air compressor

Compressed air can be supplied from an existing filtered air system or from a dedicated mobile compressor with appropriate filtration. For oil field services and refining operations, air quality is critical. Systems should include moisture separation and oil filtration to ensure consistent operation. Cold Jet dry ice cleaning systems require 100 cfm (2.8 m³/min) at 80 psi (5.5 bar).

-

After cooler (recommended)

An after cooler may be useful if you are using a portable diesel compressor as your air source. An after cooler removes most of the moisture from the system and can cool the air within 15°F (-9.4°C) of the surrounding air. This is primarily dependent on humidity levels.

-

E-CO2 150 (optional)

The E-CO2 150 was designed to significantly reduce respirable dust and secondary waste when a more abrasive clean is needed in Oil and Gas applications. It combines a dry ice blaster with a custom 1.5 cubic feet pressurized abrasive pot.

-

Reliable Dry Ice Supply

Regular access to dry ice is essential for maintaining continuous cleaning operations. Average consumption is approximately 88 lbs. per hour. Partner with suppliers who can establish a reliable delivery schedule aligned with your cleaning and maintenance schedules.

-

Machine and Operator Training

Proper training is essential for cleaning, oil field services, and fabric maintenance teams when using dry ice blasting in upstream, midstream, and downstream oil environments. Cold Jet offers a training course designed to equip your team with the skills to operate the machine correctly. The course covers important safety guidelines, essential operation techniques, and effective cleaning methods.

-

Personal Protective Equipment (PPE)

Oil and Gas cleaning and maintenance teams should be equipped with personal protective equipment, including: gloves, face shields or safety glasses, and hearing protection.

What is the best machine for dry ice blasting in Oil and Gas?

Cold Jet offers a comprehensive range of dry ice blasting machines for the entire Oil and Gas value chain. Our durable, reliable, and user-friendly machines effectively clean operational equipment without disassembly or secondary waste, helping you minimize downtime while ensuring the highest environmental, health, and safety standards.

-

Aero2 PCS ULTRA

The Aero 2 PCS ULTRA is a versatile machine for a variety of applications in the Oil and Gas value chain, from gentle cleaning with MicroParticle dry ice to aggressive cleaning with 3 mm dry ice granules.

Aero2 PCS® ULTRA -

SDI Select 60

The SDI Select 60 is designed to be a simplistic, user-friendly, and versatile dry ice blaster. It is suitable for a variety of applications in the Oil and Gas sector, enabling full pressure cleaning and gentle cleaning on delicate parts.

SDI Select™ 60 -

Aero 40FP

The Aero 40FP offers greater power to tackle even the most stubborn contaminant like heavy oil and bitumen. Its innovative air system allows for consistently powerful, pulse-free blasting.

Aero® 40FP

Why should Oil and Gas companies and Oil Field Services companies invest in Cold Jet machines?

Investing in Cold Jet dry ice blasting equipment enhances operational efficiency and safety in Oil and Gas environments. When evaluating this capital investment, consider both the return on investment (ROI) and operational benefits specific to your operations. Cold Jet machines deliver faster ROI and greater value through:

-

Durable and Efficient Dry Ice Blasters

Our machines are built for all types of upstream, midstream, and downstream environments and are significantly more durable and have a longer machine life than competitor dry ice blasters.

-

Lower Operational Costs

Cold Jet machines use significantly less consumables than competitors: dry ice, compressed air, and electricity. Effectively reducing your maintenance and cleaning expenses.

-

Accessories for All Applications

Cold Jet has the most comprehensive range of nozzles, applicators, blast hoses, and accessories for Oil and Gas applications.

-

Industry Leading Reliability

With more than 24,000 machines installed globally, we are the trusted dry ice blaster provider for Oil and Gas companies and Oil Field Services companies.

-

Unmatched Service and Training

Our regional sales and service teams understand the unique challenges in Oil and Gas environments and are always within reach. Our teams provide both service and professional operation training.

OUR CUSTOMERS & WHAT THEY SAY ABOUT US

Oil and Gas companies around the world rely on Cold Jet

With a global install base of 24,000+ that consists of companies large and small – Cold Jet delivers real value across the entire energy value chain.

WE ARE HERE TO HELP.

Interested but don’t know where to start?

Contact us today to learn more about our solutions and see how they can meet your unique needs.