Dry Ice Blasting Applications:

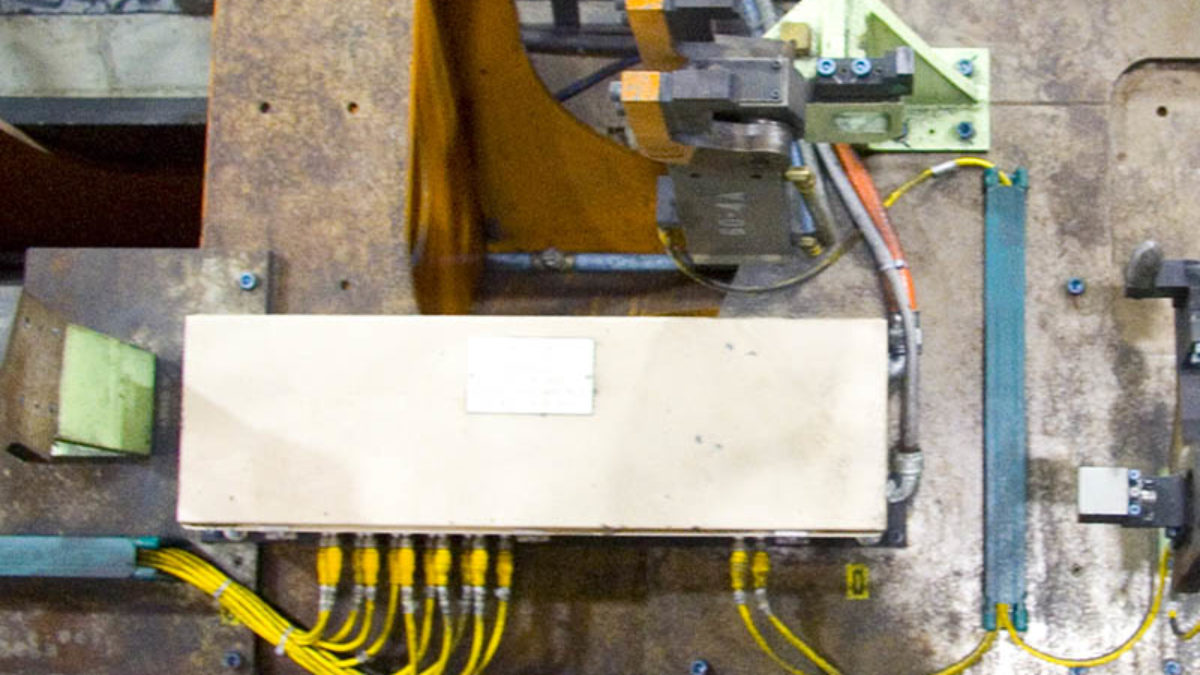

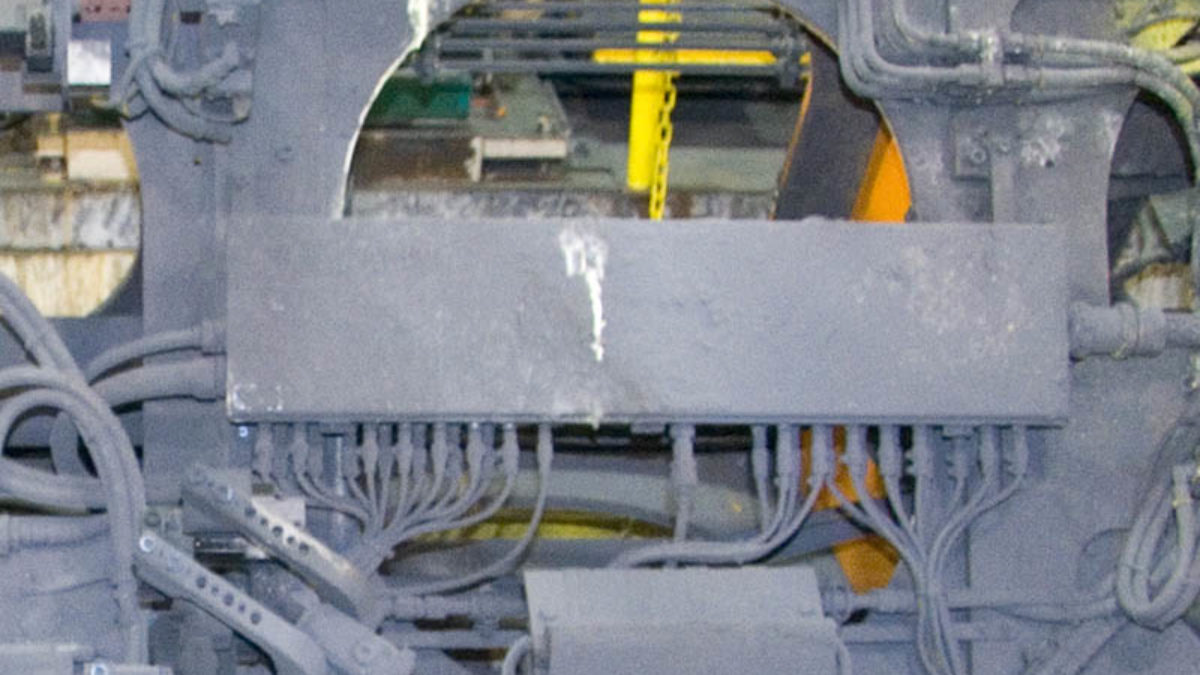

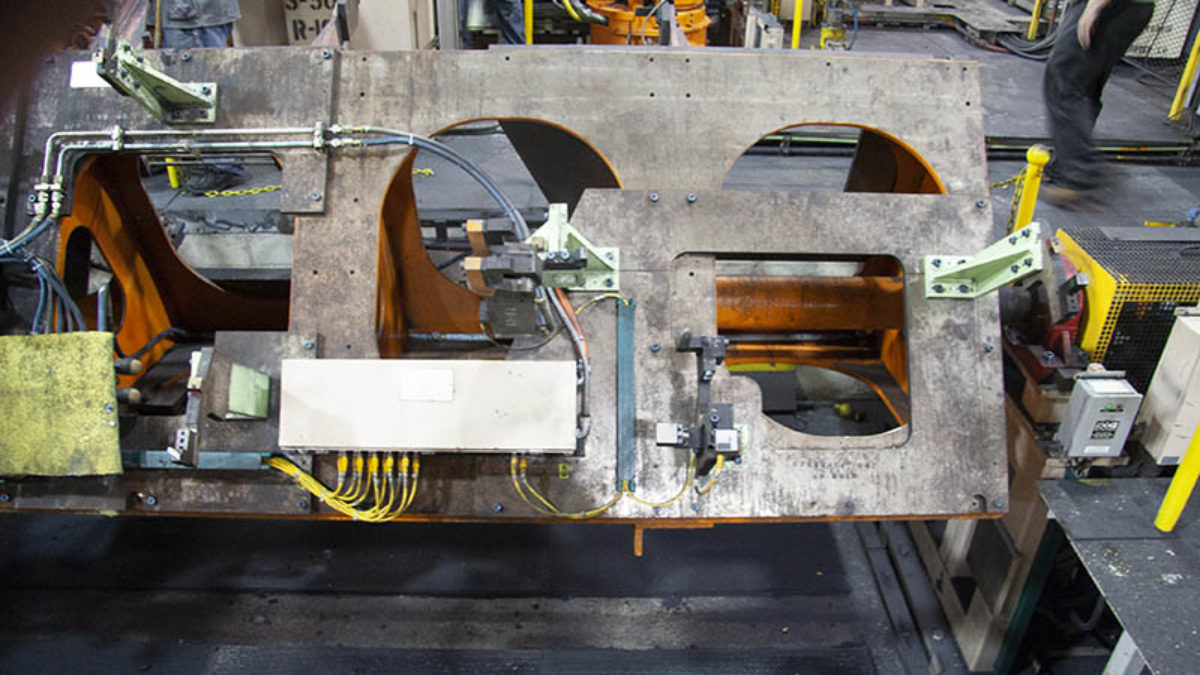

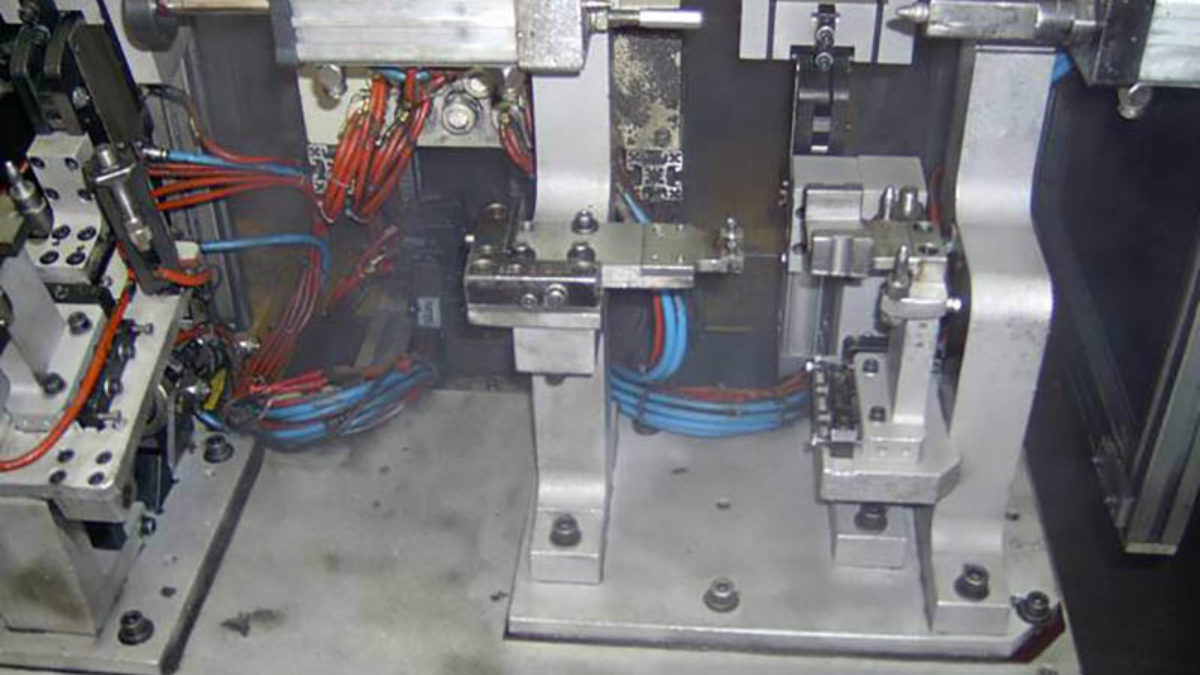

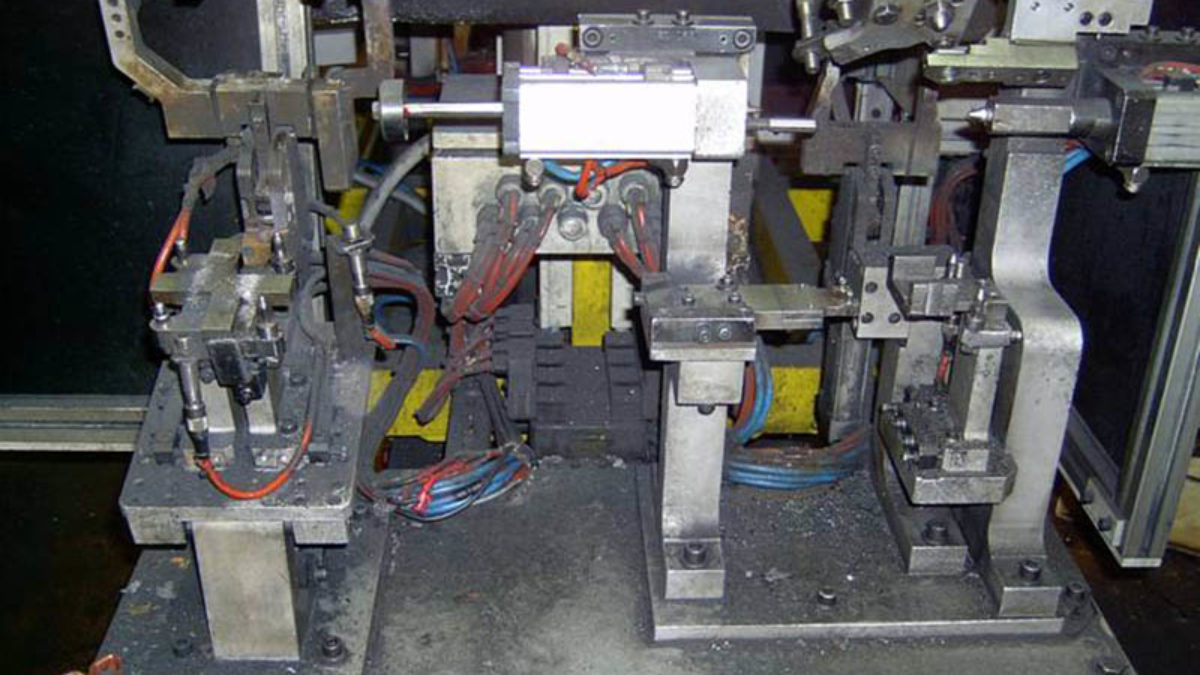

Dry Ice Blasting Equipment for Weld Line Cleaning

Improve efficiency and accuracy of automated weld lines

Dry ice blasting eliminates misalignment, breakdowns and scrap by effectively removing weld slag, spatter, resin, smoke, oil and dampering adhesive buildup from robots, production equipment and ancillary equipment. Are you looking for a better way to approach weld line cleaning? Our dry ice blasting equipment can help!

SPECIFIC USE CASES

Non-abrasive dry ice cleaning provides an effective and economical removal solution for slag and spatter build up

- Robot joints

- Transfer cases

- Shuttle jigs

- Diamond plates

- Trunnions

- Weld tables

- Fixtures

- Proximity switches

- Ancillary equipment

- +More

RELATED INDUSTRIES

Benefits of Dry Ice Blasting

Dry ice blasting eliminates welding misalignment, while reducing scrap rates and equipment failure

Always ensure your weld line is operating efficiently by implementing dry ice cleaning into your preventative maintenance plan.

- Reduce scrap rates Improve product quality

- Reduce replacement costs Maximize tooling life and decrease fixture repair

- Non-abrasive Will not damage sensors

- Eliminate manual cleaning Improves efficiencies and worker safety

- Environmentally sustainableEliminate chemicals and waste streams

- Reduce production downtime Clean faster and eliminate unplanned maintenance

- Clean on-line Minimal to no disassembly required

Case Studies

Dry ice blasting helps our customers maintain highly efficient weld lines

-

-

Contract Cleaning

Contract CleaningDry ice blasting helps contractor improve industrial robot cleaning process

Learn More

WE ARE HERE TO HELP.

Interested but don’t know where to start?

Contact us today to learn more about our solutions and see how they can meet your unique needs.