Dry Ice-Cooled Food Transportation

Ensure Food Safety, Reduce Carbon Footprint.

Dry ice ensures the safe and efficient transportation of fresh and frozen goods, both domestically and internationally, throughout the year. By maintaining consistent low temperatures, dry ice reduces the risk of spoilage and product degradation. Additionally, its lightweight nature and lower carbon emissions make it an environmentally friendly choice for the food industry.

The temperature of dry ice measures (-109 °F / -78.5 °C) and its cooling power is thrice that of water-formed ice. Microbial activity is inhibited below 40 °F (4 °C).

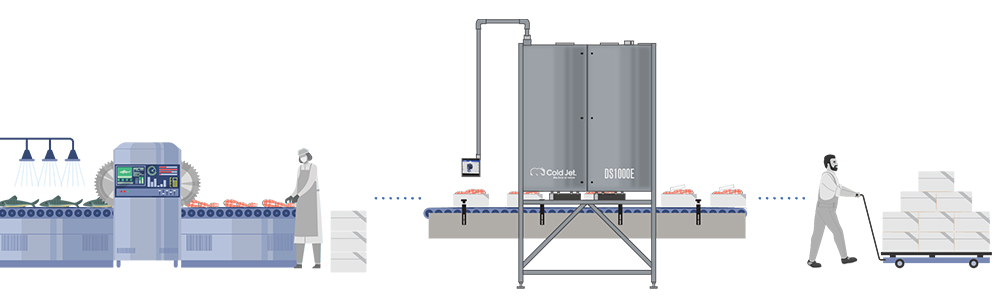

Dry Ice Cooling While Shipping Between Facilities/Processes

Dry ice is crucial for maintaining stable temperatures during the export of food products, such as protein, from processing plants to other facilities.

Benefits

By utilizing dry ice cooling, food processors and exporters can significantly increase the volume of food per box, pallet, and transport, while simultaneously reducing both carbon emissions and transportation costs.

- Product quality and safety

- Customer demand (high)

- Reduced transportation costs

- Reduced carbon footprint

- Eliminating bio pollution

Specific use cases:

- Fish (Whole, Gutted, Filleted)

- Other Seafood

- Meat (Beef, Poultry, Pork, etc.)

- Desserts & Smoothies

- Pet Food

- +More

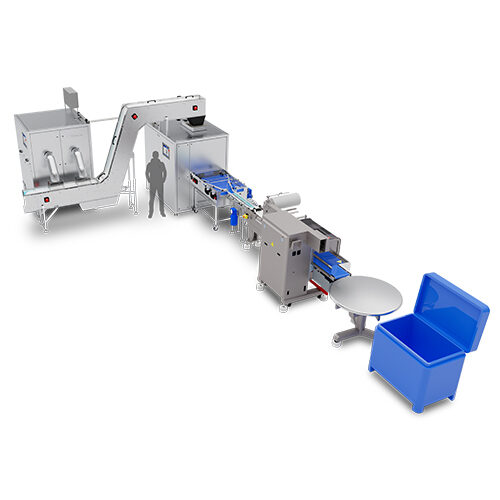

Ideal dry ice production equipment for food transportation between facilities/processes:

-

This self-contained system is perfect for food processing facilities with limited space. It eliminates the need for a separate housing unit for a Cold Jet Pelletizer.

Dry Ice Production Hub -

This dry ice slice production system is ideal for fully automated facilities. It can directly dose slices onto a conveyor, streamlining the packaging process for shipping or export.

DS1000E -

This dry ice pelletizer, equipped with a sophisticated dosing system, can accurately dispense the desired amount of pellets or nuggets onto an automated conveyor for direct packaging.

Integrated Dry Ice Dosing Systems

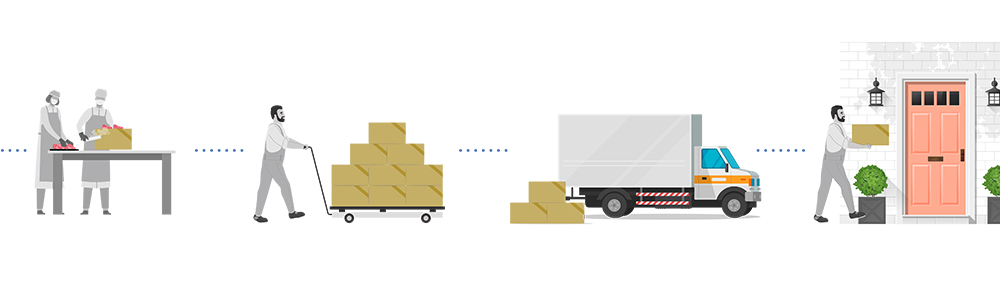

Dry Ice Cooling in Food Home Delivery

Dry ice guarantees that food deliveries from businesses and logistics companies arrive fresh or frozen, even if they’re delayed outside the customer’s door.

Benefits

Onsite dry ice production allows food home delivery services and third party logistics (3PL) companies to take control of their cold chain by providing just-in-time dry ice production solutions that eliminate the impact of supplier shortages.

- Prevent “thaws” and “leakers”.

- Ensures your clients’ food maintains critical temperatures all the way to their end customer

- Reduce shipping weight Increase margins

- Minimize food spoilage

- Rapid chilling & freezing

- Environmentally sustainable

Specific use cases:

- Meat (Beef, Poultry, Pork)

- Seafood

- Smoothies & Desserts

- Pet Food

- Meal Kits

- Groceries

- +More

Ideal dry ice production equipment for food home delivery:

-

Simplify your dry ice production process and reduce manual labor with this integrated system. It combines a Cold Jet pelletizer with a dosing and bagging system, automating the packaging of pellets or nuggets.

Dry Ice Dosing & Bagging -

Produce and package a wide range of dry ice slice sizes in branded packaging with a fully automated flow packer. This system prioritizes both operator and customer safety.

R Series -

Start your dry ice production journey with a Cold Jet Pelletizer. Choose from models capable of producing 80 to 750 kilograms per hour.

PR350H

Dry Ice as a Cost-Effective Alternative to Water Ice, Gel Packs and Phase-Changing Materials (PCMs)

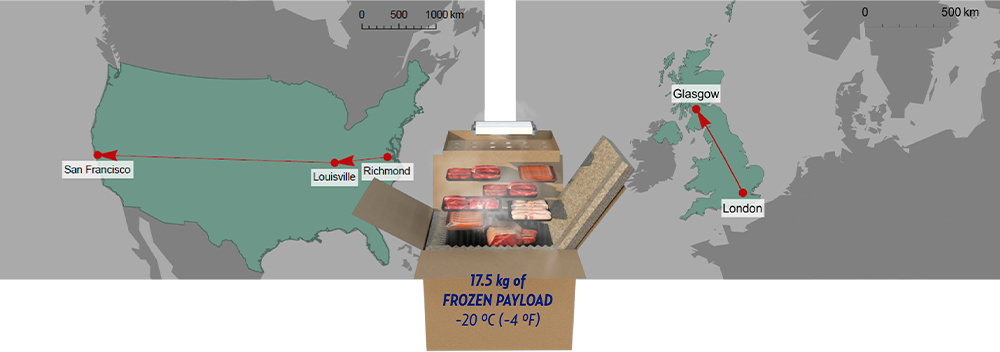

Cold Jet has partnered with German-based SmartCAE, a team of logistics experts, to conduct a comprehensive Thermal Lane Risk Assessment. This study compares the effectiveness of dry ice, gel packs, and phase-changing materials as passive cooling agents.

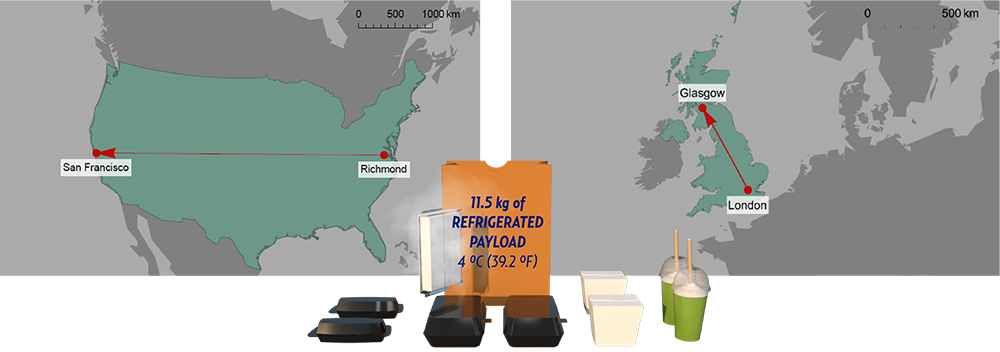

The assessment covers various shipping scenarios, including frozen and fresh food, 72-hour and 24-hour lanes in the US, and 48-hour and 24-hour lanes in the UK. Both EPS and sustainable cardboard boxes were considered. The findings are as follows:

Frozen Food Delivery

When using EPS boxes, frozen shipments on this route require twice the weight of PCM bottles compared to dry ice slices to maintain consistent temperatures year-round. When switching to a more sustainable cardboard box option, the weight of PCM bottles needed increases by 85-87% compared to using dry ice slices.

Shipment of Refrigerated Food

When using either EPS or cardboard boxes, refrigerated shipments may require two to three times the weight of gel packs and PCM bottles compared to those using dry ice slices.

When food safety is on the line, shippers and 3PLs trust in Cold Jet.

WE ARE HERE TO HELP.

Interested but don’t know where to start?

Contact us today to learn more about our solutions and see how they can meet your unique needs.